Basic resources are rolled into a factory, followed by loud noises and a smoking chimney. On their journey toward becoming final products, raw materials go through work in process inventory. The chief advantage of these systems lies in unified access to real-time production data.

Written by True Tamplin, BSc, CEPF®

Next, the assembled table is sent to varnishing, whereupon the required amount of varnish also becomes part of WIP, along with the now assembled table. The value of the WIP inventory consists of the values of raw materials, labor, and manufacturing overhead costs accrued within manufacturing it until the table is finished and ready for shipment. Total manufacturing cost represents the total costs of all manufacturing activities for a financial period. It is calculated as the sum of the total costs of raw materials, labor, and overheads used in manufacturing for the period.

- Businesses can ensure smoother operations, better financial management, and more predictable outcomes by understanding, managing, and optimizing WIP.

- It is often used in a professional context to indicate that feedback or input is welcome.

- Designing optimized storage and shop floor layouts and considering WIP inventory volumes already in the production planning phase is also a must.

Dictionary Entries Near work in progress

In 2018, Tesla faced challenges with their WIP as they ramped up production for the Model 3. By streamlining specific production processes and optimizing their WIP, they increased their output significantly within a year. This example highlights the practical significance of efficient WIP management.

Table of Contents

Work In Progress (WIP) refers to the intermediate goods or unfinished products that are at various stages of the production process but still need to be completed. The beginning work-in-process inventory represents the value of all unfinished goods at the beginning of the new accounting period. In other words, it is the WIP asset section of the balance sheet of the previous accounting period.

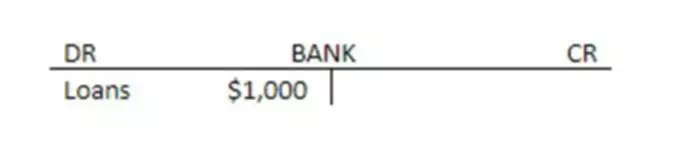

We use these three figures to calculate ABC’s raw material inventory. After the product is sold, WIP cost is one among several costs that are rolled up to determine the final cost of goods sold in the balance sheet. As such, the difference between WIP and finished goods is based on an inventory’s stage of completion relative to its total inventory. WIP and finished goods refer to the intermediary and final stages of an inventory life cycle, respectively.

According to The Free Dictionary, the abbreviation WIP also has a plethora of other potential definitions. While these are still valid, they are far less common than using WIP to mean work in progress and should therefore be used sparingly. If you do decide to use one of these alternate definitions for WIP, you should make sure that you provide the reader with the proper context so that they can discern the intended meaning.

It is used by individuals who want to indicate that their work is still in the process of being completed or refined. In real-life scenarios, you may come across it written on a note attached to a drawing or digitally in an email with a design attached, or in a description about source code uploaded to a repository. WIP has been used as an abbreviation for “work in progress” since at least the 1960s. Since it is often pronounced as a word (whip), it is considered an acronym. Work In Progress (WIP) offers insight into the efficiency and effectiveness of a production process or any activity in progress.

Understandably, all companies need to be focused on their cash flow and overall financial health. While larger companies can absorb a few more errors due to scale and averaging, small and medium-sized companies often have little to no room for error. Here are five reasons why accurate WIP accounting is a must, regardless of company size. The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly.

It is often used in a professional context to indicate that feedback or input is welcome. Such advancements underscore the evolving nature of WIP management in today’s digital age. The periodical WIP inventory calculation is informed by three important accounting metrics. These are the beginning WIP inventory value, the total manufacturing cost, and the cost of manufactured goods, also known as COGM.

It could be useful to know the WIP inventory for tax purposes to calculate one’s manufacturing costs. In production and supply-chain management, the term work-in-progress (WIP) describes partially finished goods awaiting completion. WIP refers to the raw materials, labor, and overhead costs incurred for products that are at various stages of the production process. WIP is a component of the inventory asset account on the balance sheet. These costs are subsequently transferred to the finished goods account and eventually to the cost of sales. Work In Progress (WIP) is a term commonly used in the manufacturing and production sectors to denote partially completed products that have not reached the final stage.

Since manufacturing is a dynamic process of multiple constantly-moving parts, it is difficult to accurately calculate and account for WIP costs for each product. WIP is commonly used online to mean “work in progress” when presenting or discussing artistic work that’s not done yet. The term WIP can be used in many different sentences to refer to things that are in progress, from supply chain management to a painting and more. It is a very universal term that can be used in a variety of different circumstances and settings. In this example, Rayne’s mom is frustrated with his homework progress. To end this article, let’s take a look at why effectively managing and keeping WIP inventory as slim as possible is also good from a production and inventory management viewpoint.

Synonyms are also useful to know if you are trying not to repeat yourself or if you are looking to expand your vocabulary. In the broader context, WIP can be applied to any task, project, or activity that has begun but is not yet finalized. Understanding and managing WIP is vital as it helps businesses monitor efficiency, manage resources, and predict final output or completion. Mattias is a content specialist with years of experience writing editorials, opinion pieces, and essays on a variety of topics. He is especially interested in environmental themes and his writing is often motivated by a passion to help entrepreneurs/manufacturers reduce waste and increase operational efficiencies.

Businesses need to accurately calculate the cost of WIP, which includes raw materials, labor, and overheads, to ensure that the total inventory values are accurate. This, in turn, affects the financial statements and the company’s profitability metrics. When combs are manufactured, plastic is moved into production as a raw material. Since the combs are only partially completed, all costs are posted to WIP. When the combs are completed, the costs are moved from WIP to finished goods, with both accounts being part of the inventory account. Costs are moved from inventory to cost of goods sold (COGS) when the combs are eventually sold.

When a guy uses the term WIP to a girl, it could imply different things. It could signify a compliment to her work or a way of appreciating her creative abilities. There are many people who omit the aspirate in most words which begin with wh; as white, whip, &c. Literally it means Work In Progress (WIP) as previous answers correctly point out. However, it does not occur only on GitHub, but can happen also on any other competitive platform, e.g. Find centralized, trusted content and collaborate around the technologies you use most.